Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

Years of

Experience

Lingxian Sunshine Conveying Equipment Co., Ltd. was founded in 2012 , which is located in the town of mesh belts in China.

For many years, it has been focusing on the manufacture and sale of conveyor mesh belt, chain, sprocket, chain plate,conveyor, dryer and Instant noodles machine parts etc. They are widely used in automated production lines, food processing, medical treatment, textile industry and so on.

Sunshine all products will make you absolutely satisfied, we always follow the customer first production concept, strive to open up domestic and foreign markets and are willing to establish long-term business cooperation with each customer. Welcome friends from all walks of life to come to guide, discuss cooperation!

Industry Experience(years)

Area(㎡)

Annual Output Value(million)

Accumulated Customers

Wire mesh belt conveyor can be divided into mesh belt type and network chain, conveyor can transport material horizontally, obliquely and vertically, It can also form a space conveyor line.The conveying capacity of Conveyor is large, and the conveying distance is long, it can also finish several technological operations during transport.

Therefore, it is widely used in food, daily necessities, pharmaceutical, animal husbandry, aquatic products, clothing processing and other industries, the material,width and shape of mesh belt can be selected to meet horizontally transport and turning, lifting, declining and so on.

Feartures:

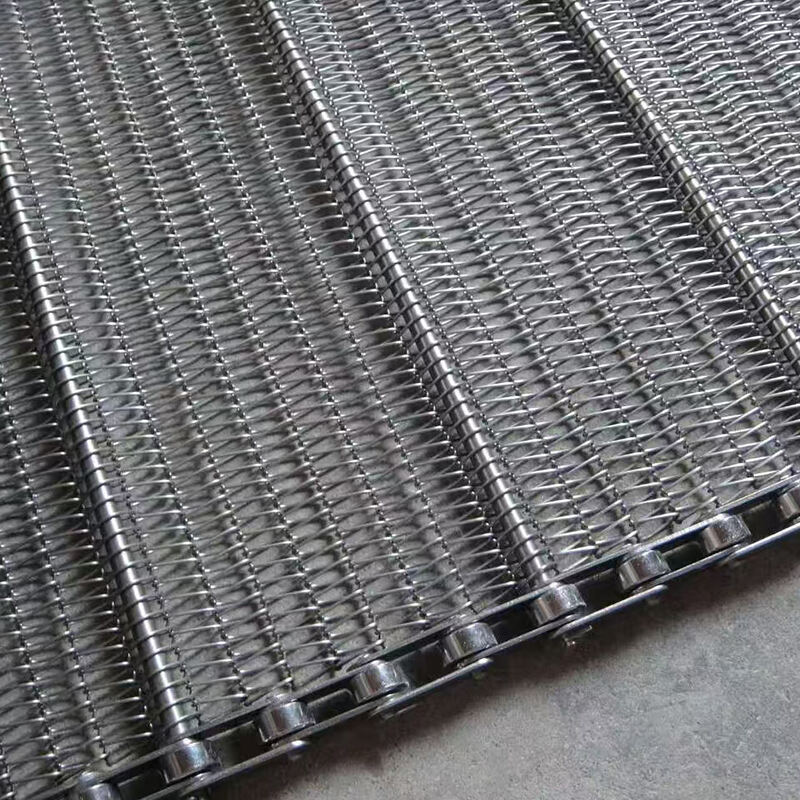

1、Also known as U-shaped chain, made by cross rod and metal sheet. Firm and durable,very little maintaince is needed ,with long life.

2、May customized lockstitching style in two sides of rod according to requirements, or offer side baffle guard and transverse baffle.

3、Material common used carbon steel, galvanized steel, stainless steel 304 and 316.

4、Mesh hole big,weight is light, convenient to transportation.

5、Surface smoothly, running stable,can’t go astray.

Features:

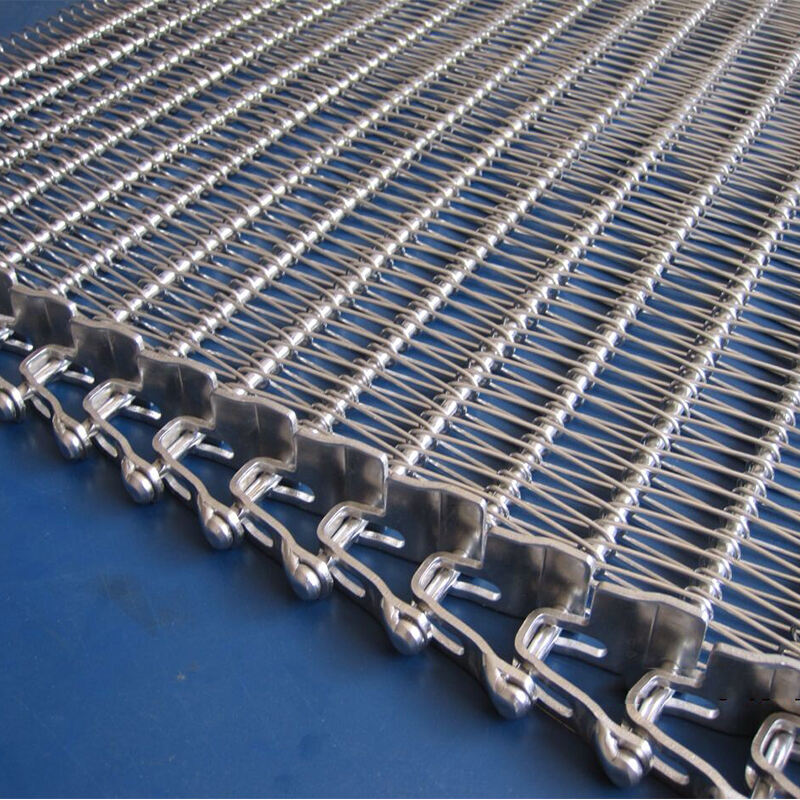

1、Made by high elasticity flexible stainless steel wire, single layer structure, light weight.

2、Hole area large(70-85% open ) good air circulation.

3、Mesh belt common use single layer construction,driven by sprockets.

4、Go straight or turning ,customized dimension according to requirements.

The mesh belt is a conveying equipment that is mainly used to convey materials. It has the characteristics of flat mesh, high hardness, strong corrosion resistance, high tensile strength, good air permeability, not easy to deform, and durable.

There are many materials and types of mesh belt. Metal mesh belt have high strength, high wear resistance and corrosion resistance, and are widely used in industrial automation production lines. Nylon, polyester and other polymer material mesh belts have good wear resistance and flexibility, suitable for light load, low speed conveying scenarios, mesh size, pitch width, type can be customized according to actual use needs.

The products are mainly used in: glass bottles and jars, food, metal, utensils, chemical fiber, printing and dyeing, medicine, electronics, powder metallurgy, heat treatment, wood, logistics and other industries automatic devices and automatic assembly lines; The transmission and use of various kiln systems such as natural gas, coke oven gas and electronic infrared; Conveyor belts for food machinery, glass machinery, conveyor machinery.

The herringbone mesh belt, also known as the overlapping mesh belt, is a variant of the double-rotating mesh belt, which is made up of left-handed and right-handed mesh strips in turn to form a very tight and flat mesh surface, usually using a straight shaft, but some specifications can also use a crankshaft.

The tightness of the herringbone mesh belt makes it ideal for conveying small products such as nuts, bolts, screws, nails, cookies, chemical pellets, etc.

Features :

1. Made by imported digital mesh weaving machine, hole well –distributed, surface smooth and beautiful.

2. Common material including stainless steel 304 or 316, use for conveying food,clean and nontoxic.

3. Mesh surface is tough and durable,distortion-resistant, can bear high pressure and stress.

4. Two sides adopt U-shaped roller chain,has very good turning capabilities and can go 180 curves. And runs smoothly.

5. Has good air circulation and easy-cleanable, convenient to maintain and dismantle.

6 .Customized kinds of specification according to customer’s requirements. May add side guard or not add mesh wire.

The spiral cooling conveyor, also known as the spiral cooling tower, uses stainless steel spiral mesh belt as the carrier, and the whole machine is made of stainless steel, which is a specially designed equipment for rapid cooling, and its core principle is to enhance air circulation through the spiral cooling design, so that the cold air can efficiently take away the heat in a continuous cycle. It has the advantages of small footprint, good turning performance, large and stable conveying capacity, continuous and uninterrupted. The spacing and number of layers per layer are customized according to the output, and the cooling time is 20-120 minutes, which is suitable for the needs of modern production lines.

It is mainly used in food processing, used to cool baked goods such as bread, cakes, hamburgers, toast, etc., to ensure that the food maintains a uniform temperature during the cooling process, and can also be used for dough proofing and quick-freezing, frozen transportation of fried food, seafood and other frozen meat in the slaughterhouse. It can also be used in electric power, steel, chemical, pharmaceutical, metallurgical and other industries for heat dissipation and cooling, improving production efficiency and ensuring product quality.

Characteristic:

1. The plate link conveyor is flat, friction is small, material can be transmitted between conveyor line.

2. The plate link is divided into stainless steel and engineering plastics, the material of rack is divided into aluminum, carbon steel and stainless steel, the specification is various, which can be selected according to material and technological requirement, it can meet different demand with different industries.

3. The conveying capacity is large, which can bear larger load, it is widely used in electric vehicle, motor bicycle, generator and so on.

4. The conveying speed is exact and steady; it can ensure exact synchronous transmission.<br>

5. The layout of equipment is flexible, which can do the horizontal, inclined and turning transmission work.

Application:

It is widely used in food and beverage, hardware and electrical appliances, communication electronics, medicines, detergents, paper products, tobacco and heavy materials for automatic transportation, distribution, and post-packaging line transportation.

Features:

1) Chain plate belt is made of high quality metal sheet with robust surface and driven by chains; used for conveying very small products and top heavy loads.

2) Suit for medium and heavy products transportation, big load capacity and durable.

3) High flexibility , make it level, tilt ,overturn and other difficult works in one process of transport line.

4) Punching can be customized used in different fields, to meet the different needs of all walks of life.

Applications:

It is widely used in vehicles, electrical assembly lines, animal slaughtering production lines, detergents, paper products, food and dairy and tobacco automatic conveying, distribution and post-packaging line conveying, as well as glass products and castings cooling and conveying.

Provide design suggestions and drawings for free.

We can make them according to your drawings or samples.

Customize non-standardized products according to your needs

Sample reference comparison can be provided

Installation engineer to guide the whole process

Provide quality assurance, worry-free after-sales

Sunshine all products will make you absolutely satisfied, we always follow the customer first production concept.

Physical factory, all products are processed and made by ourselves, and product photos are taken really, so you can come to the factory for inspection.

With more than 20 years of experience in the conveying equipment industry, the professional R&D team can provide you with the best product solutions.

Independent research and development of a number of conveying equipment patents, is a national high-tech enterprise.

It has advanced automated production and welding equipment, exquisite workmanship and small error.

As a supplier of many large enterprises, we have rich experience in the R&D and production of large-scale conveyor lines.

More than 10 years of export experience, the products have EU CE certification, and there are overseas offices and showrooms in Indonesia.

Products of any size and material can be customized, and we have professional engineers to achieve your satisfaction.

We can design and produce a complete set of conveyor lines, if we encounter equipment that we can't produce by ourselves, we will inform you and help you purchase, and we can provide all related parts.

It is generally about 10 working days for small equipment, and it may take 2-3 months for large equipment.

The products are generally packaged in special wooden boxes for export, and there are long-term cooperative freight forwarders to ensure fast delivery and low cost.

We have professional installation engineer guidance, if we really need we can also come to the door to install.

We can assist in issuing relevant visa information, and we will receive and accompany you throughout the process

At this week's weekly meeting, Zhang Gong summarized the feedback of customers on the use of products in the past week, and the overall response was good, and he expressed satisfaction with the company and the product, and several small problems in t...

On January 5, 2025, our company sent a set of large PU conveyors to a winery in Sichuan. We are fully responsible for the design, production, installation, commissioning and other matters of this conveying project, and the installation team also rush...

As early as 2015, the company compiled the mesh belt instruction manual, with the continuous introduction of new products and technology updates, the old version of the mesh belt instruction manual has not been able to adapt to the development of the...