Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

The mesh belt is a conveying equipment that is mainly used to convey materials. It has the characteristics of flat mesh, high hardness, strong corrosion resistance, high tensile strength, good air permeability, not easy to deform, and durable.

There are many materials and types of mesh belt. Metal mesh belt have high strength, high wear resistance and corrosion resistance, and are widely used in industrial automation production lines. Nylon, polyester and other polymer material mesh belts have good wear resistance and flexibility, suitable for light load, low speed conveying scenarios, mesh size, pitch width, type can be customized according to actual use needs.

The products are mainly used in: glass bottles and jars, food, metal, utensils, chemical fiber, printing and dyeing, medicine, electronics, powder metallurgy, heat treatment, wood, logistics and other industries automatic devices and automatic assembly lines; The transmission and use of various kiln systems such as natural gas, coke oven gas and electronic infrared; Conveyor belts for food machinery, glass machinery, conveyor machinery.

The mesh belt is a kind of machine which adopts the method of static friction, which is used to drive the material in a continuous way. Apply it, the material in the transmission line, feed point from the initial to final unloading material formed of a material conveying process. It can not only carry on the transportation of the crushed material, but also can carry on the transportation of the goods. In addition to the purely material handling, but also can be compatible with the requirements of the process in the various industrial enterprises in the production process, the formation of the rhythmic flow transport line. Different environments using the mesh belt material are different, such as carbon steel, galvanized iron wire, spring steel, stainless steel, plastic and so on. The choice of material is decided by different working environment.

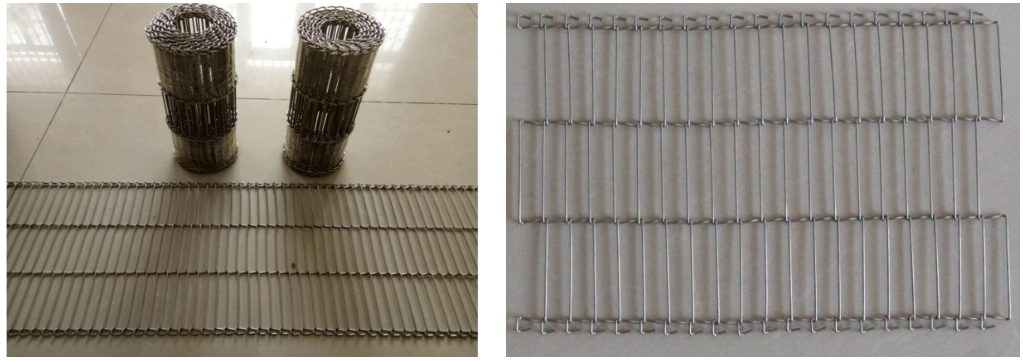

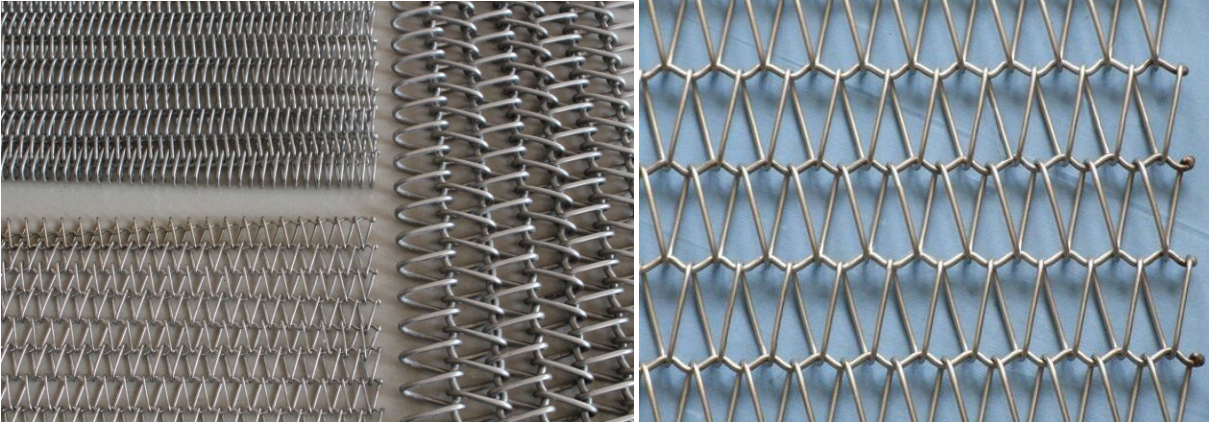

Mesh Belt has many varieties and specifications, mainly has the following several: Balanced weave wire mesh belt, Chain type stainless steel mesh belt, Plastic mesh belt, Rhombus mesh belt, Spiral wire mesh belt , Honeycomb Belt , Flat Flex Wire Mesh Belt , Eye link belt , Food baking Mesh Belt , Quick freezing mesh belt, Glass Annealing Mesh Belts , Flat wire mesh belt , Herringbone mesh belt etc. The width between 10mm-10000mm.

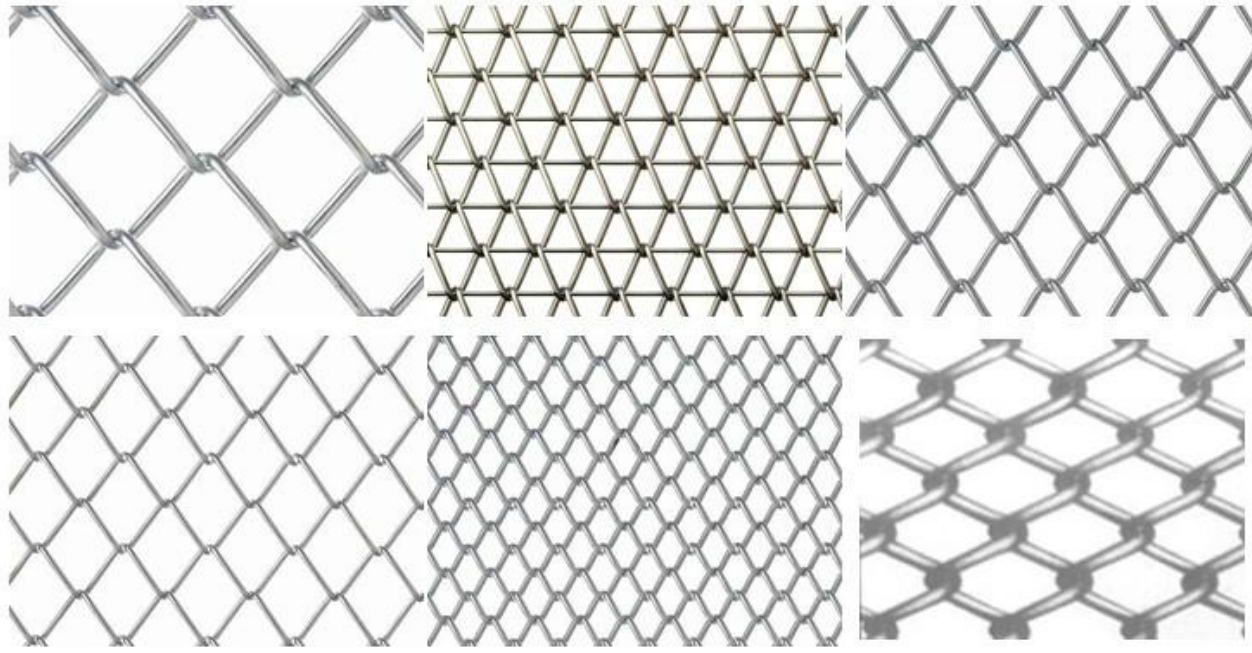

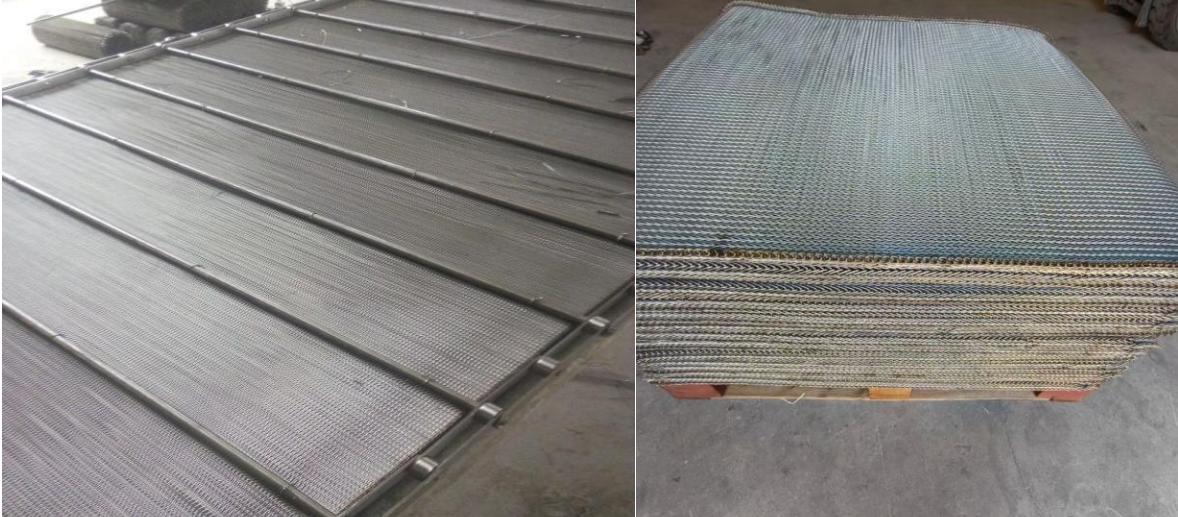

As it’s shape is rhombus when we woven, so we call it rhombus mesh belt.

Features:

1, Materials include carbon steel , galvanized wire, spring steel, thermostable stainless steel.

2, Good flexibility, smooth delivery

3, Large mesh, breathable, the size can be adjusted according to the volume of material to be transported.

4, We can make it with chains on both sides if you need.

5, Easy to clean, installation, maintenance and removal.

Applications:

Rhombus mesh belt is widely used in industrial and manufacturing, food’s drying,&washing, cleaning of mechanical parts etc.

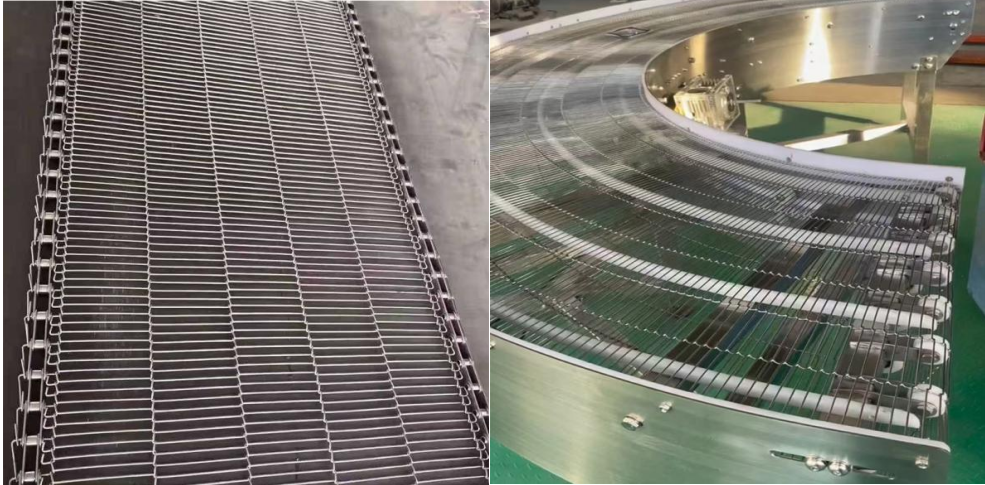

Features

1. Made by imported digital mesh weaving machine, hole well –distributed, surface smooth and beautiful .

2. Common material including stainless steel 304 or 316, use for conveying food,clean and nontoxic .

3. Mesh surface is tough and durable,distortion-resistant, can bear high pressure and stress.

4. Two sides adopt U-shaped roller chain,has very good turning capabilities and can go 180 curves. And runs smoothly.

5. Has good air circulation and easy-cleanable, convenient to maintain and dismantle.

6. Customized kinds of specification according to customer’s requirements. May add side guard or not add mesh wire.

Range of use:

Spiral wire mesh belt specialized in multi-layer spiral equipment for food industrial, and applied to need turning equipment . It is mainly used food fermentation, cooling, quick-frozen and baking. Such as quick-frozen pisa, fish sticks, dumpling, rice dumpling, baking bread,cake, baked bun, little snacks.

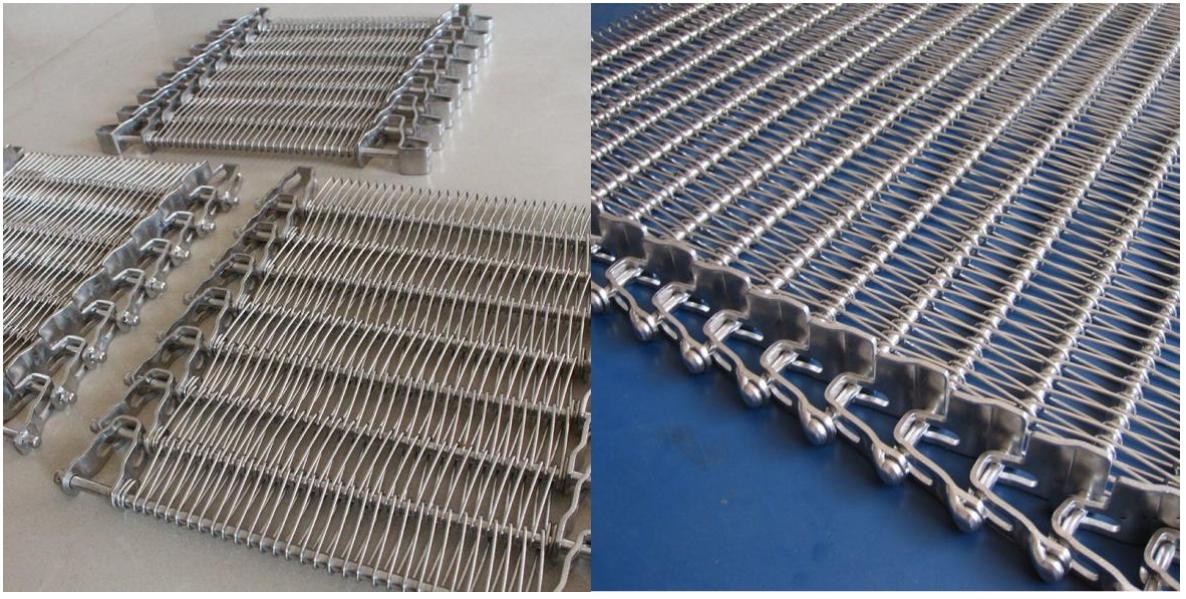

Feartures:

1. Also known as U-shaped chain, made by cross rod and metal sheet. Firm and durable,very little maintaince is needed ,with long life .

2. May customized lockstitching style in two sides of rod according to requirements, or offer side baffle guard and transverse baffle .

3. Material common used carbon steel, galvanized steel, stainless steel 304 and 316.

4. Mesh hole big,weight is light, convenient to transportation.

5. Surface smoothly, running stable,can’t go astray.

Range of applied:

Widely used automatic line conveying such as light industrial machinery, sterilizers, silk printing and dyeing,food processing,power generation, pharmaceuticals, garment processing,etc .used for conveying line washing,drying,cooling, heat treatment, bread line,spiral tower conveying in refrigerating machinery, spraying, cleaning machine,and Heavy transport machinery etc.

Features:

1. Made by high elasticity flexible stainless steel wire, single layer structure, light weight.

2. Hole area large(70-85% open ) good air circulation .

3. Mesh belt common use single layer construction,driven by sprockets.

4. Go straight or turning ,customized dimension according to requirements.

Range of applied:

Used for light products cooling,frying,baking,drying, heating, decoration, coating flour

And packing equipments etc. such as :snack,pisa,bread, biscuit,chocolate,nuts and fruit conveying.

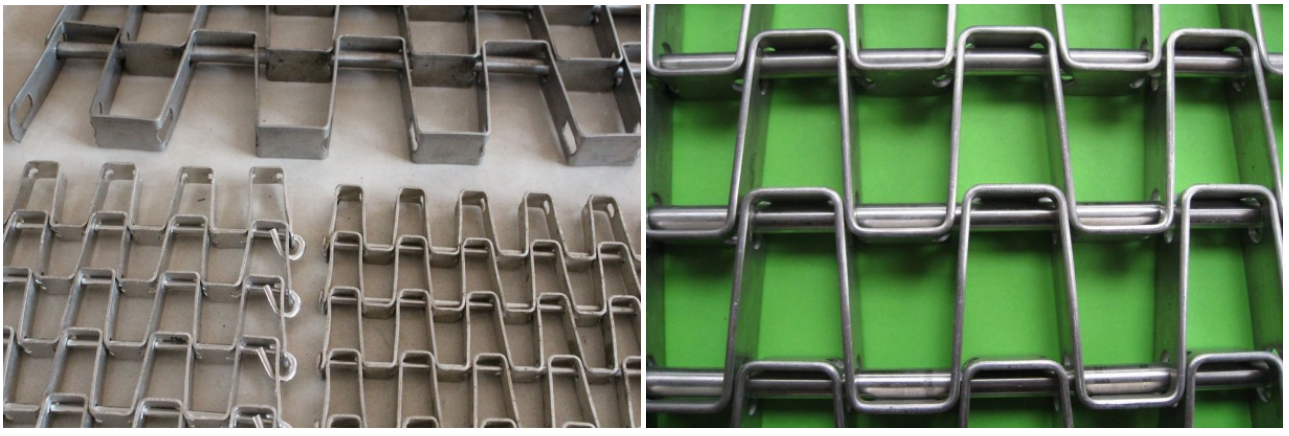

Features:

1. Made by round mesh wire shaped glass then string up by cross rods,light weight,easy to clean,driven by sprockets or roller drum.

2. Running smoothly,easy to maintaining.

Range of applied:

Usually used for following applications :freezing , Foundryequipment, quench tanks, dehydration equipment, sterilization equipment, drying equipment, steel blast equipment, filtering equipment, packing equipments, baking stove ,cooling equipment, Blanching equipment , Storage Equipment, shrinkable packaging device washing machines etc.

The great advantage of the belt is adopting 304 and 316 stainless steel, which has the characteristic of high temperature resistance, anti-corrosion, moisture- proof, the surface of the belt is clean and non-poisonous as well as pollution-free and environmental-protection, the belt is widely used in glasswork industry, such as annealing furnace mesh belt, decorated furnace mesh belt, it is also used in baking pizza, roasting ham, dehydrated vegetable,quick-frozen food, cleaning machine, drying machine, dryer, curing oven, etc.

The characteristics of glass annealing mesh belts are smooth surface, strong hardness, high anti-corrosion, uneasy deformation, durable and so on.

Glass annealing mesh belts is widely used glass container, foodstuff, lamp, metal ware, chemical fiber, electron, powder metallurgy, thermal treatment as well as natural gas, coke oven gas, infrared ray, etc.

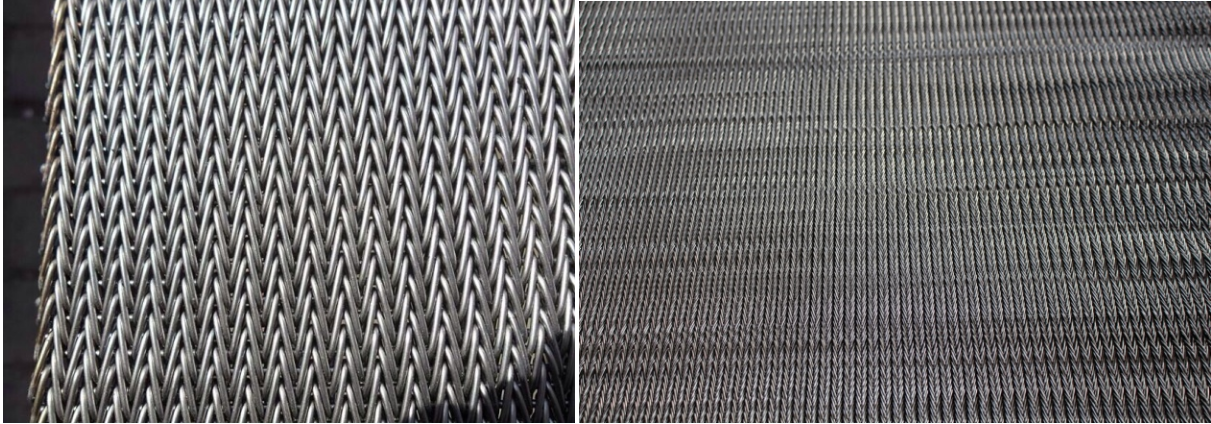

Flat wire mesh belt is made of flat steel wire, the characteristic is smooth, steady and non-slip, the material is mainly carbon steel wire and stainless steel wire.

It is mainly used in food production line, the specification has herringbone mesh belt and rhombus mesh belt, which are largely used in biscuit industry and popular with biscuit manufacturer.

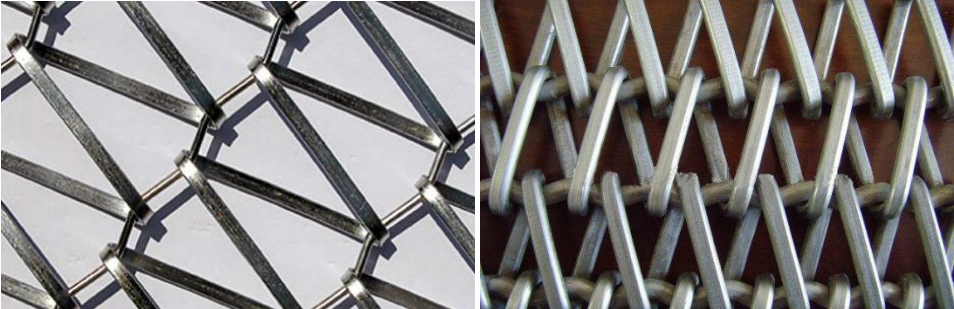

Herringbone mesh belt is a variation of balanced weave belt,Right hand and left hand weave forms a very dense and smooth belt with most rod straight and some crimped.The belt is perfect to convey small products because of high dense mesh,such as nuts,bolts,screw,nail,cookies,chemical grain etc.

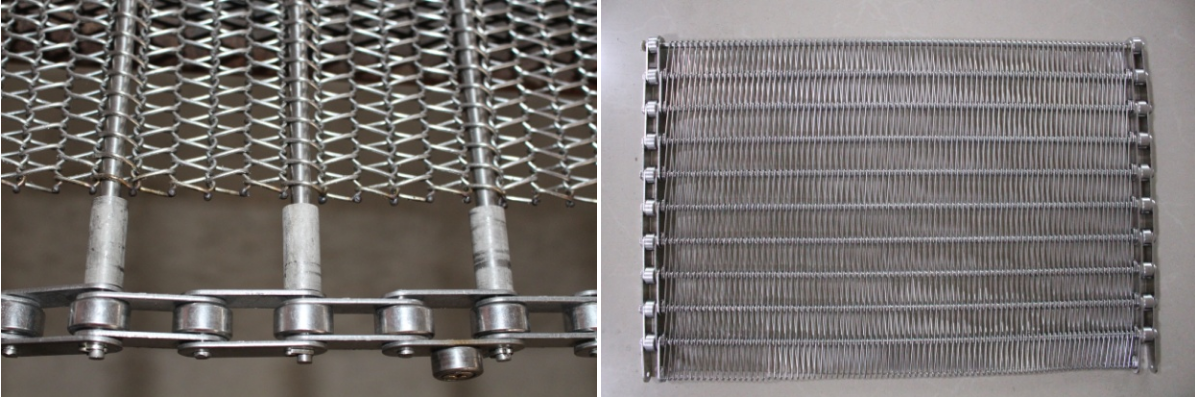

Chain type stainless steel mesh belt are driven with a cross rod which connects the chain strands by either passing through or under the wire mesh fabric.The density of wire mesh fabric is choosen according to size of the product conveyed on the belt.

Chain type stainless steel mesh belt characterics:positive drive,smooth running,little pressure on wire mesh fabric,from minus 55 degrees to 1150 degrees,side guard and flight available,material:carbon steel,galvanized steel,stainless steel,weathering steel,high temperature steel,ususally used in baking oven,quenching tank,washing machine,fryer,freezer etc.

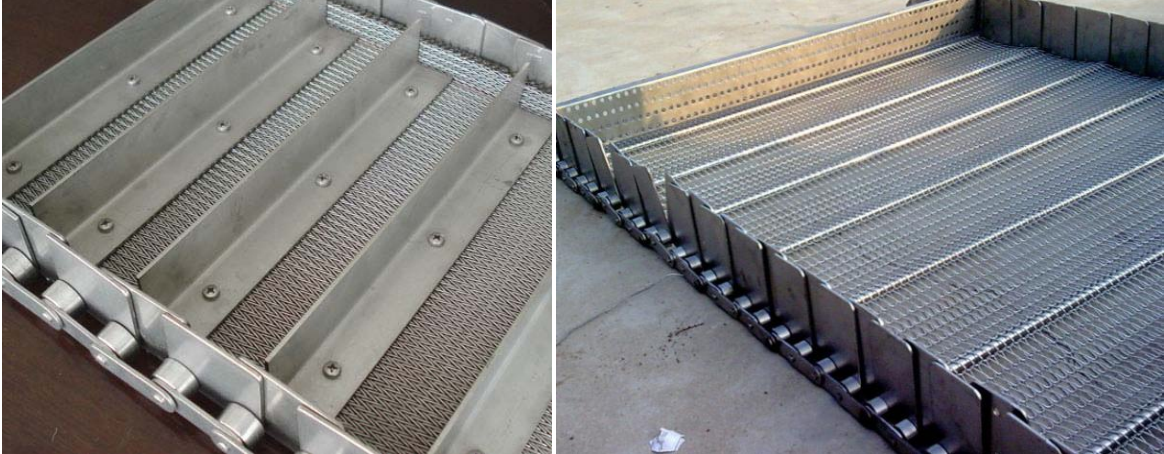

Belt with side guard & flight is roller chain driven belt assembled with side guard and flight and used for separating,filtering and elevating goods.Shapes and specifications of side guards and flights depends on specific applications.

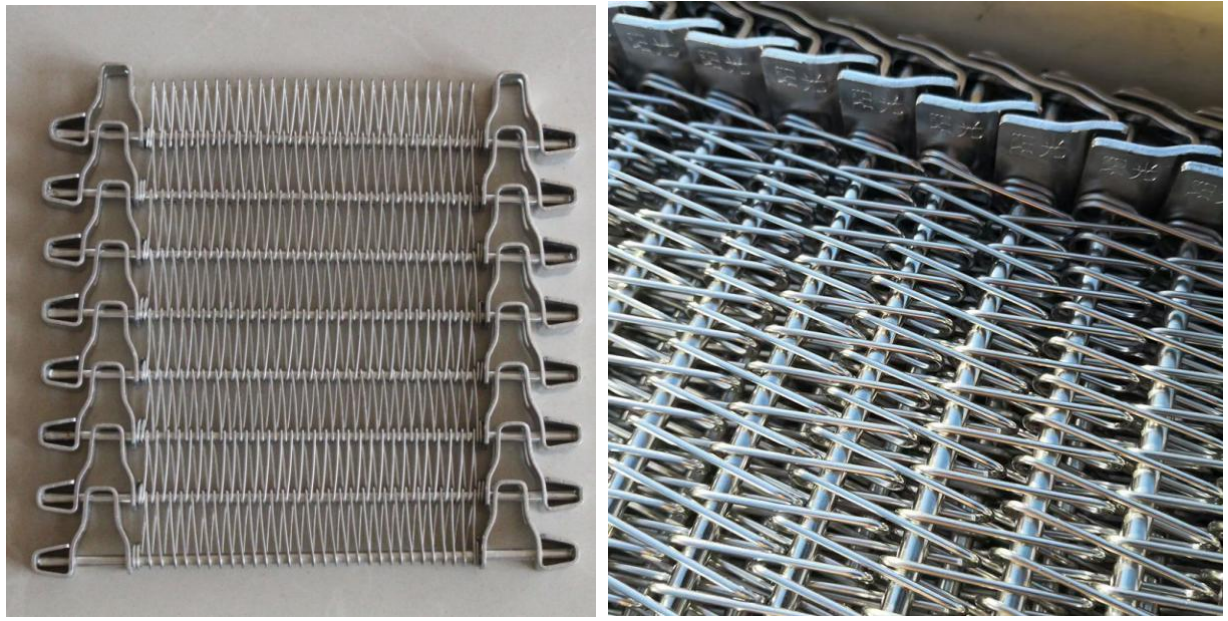

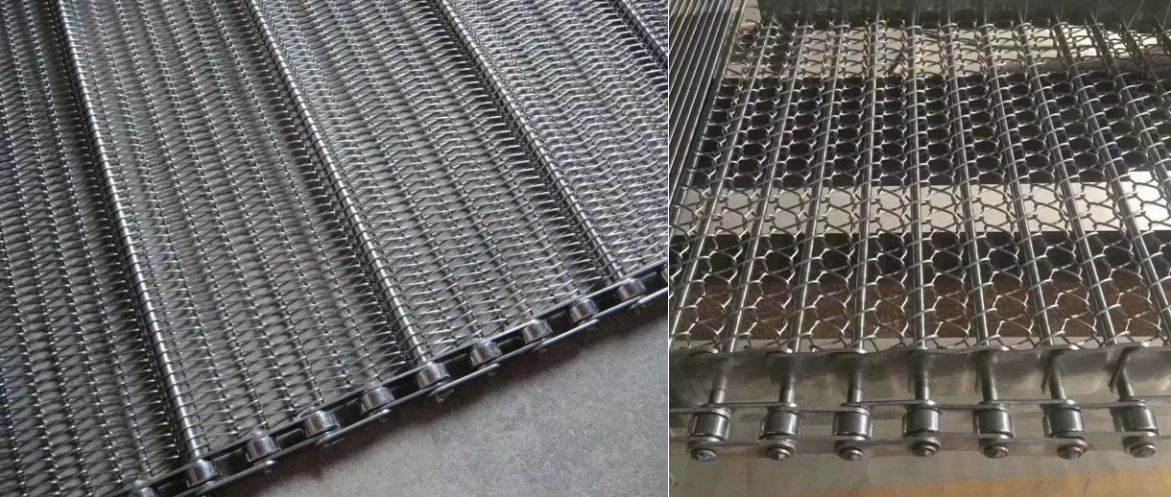

Consists of alternating right and left hand spirals connected with a crimped or straight connecting rod to create a balanced weave.

Belt with crimped rods:This style combines all advantages of wire mesh belt.The crimped rod guarantees all spirals in right position to prevent distortion and stretch.

Belt with straight rods:Consists of alternating right and left hand spirals connected with straight connecting rods.Holes are very small and well-distributed and it guarantees smooth belt running.This style is perfect for small and heavy products.

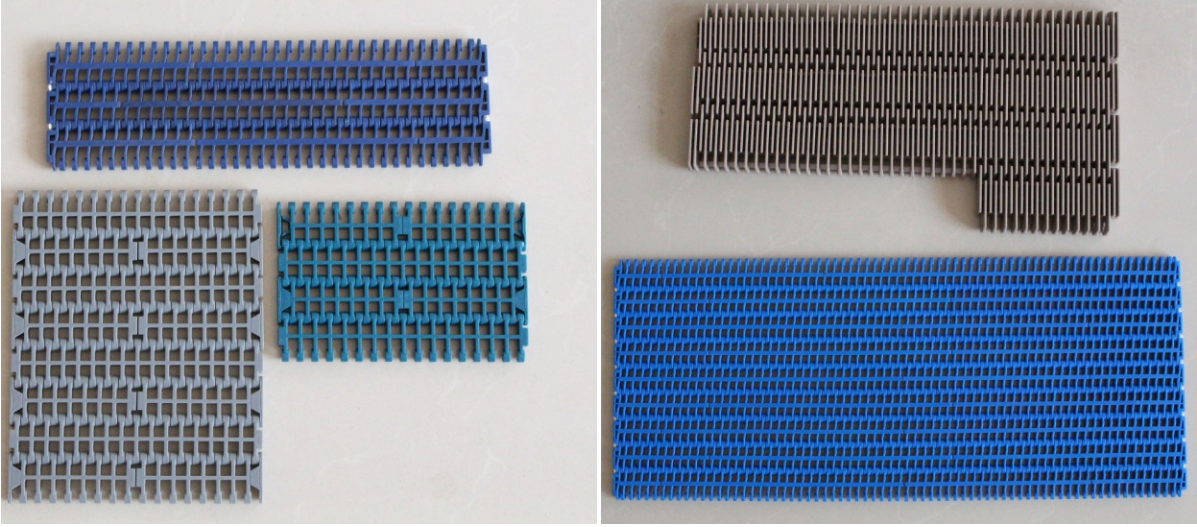

Plastic mesh belt is made of engineering plastic chain plate assembly and, modular mesh belt in an interlocking or bricks are mutually staggered, and by the full-length pin rod are assembled together, this design fundamentally improves the strength of the conveyor belt. The baffle and the side panels can be interlocked using hinge pins, one of the components of the conveyor belt as a whole. The plastic mesh belt has various forms, flexible assembly and convenient replacement. There are open hole form, flat plate, convex rib, ball, slip and other forms. Applicable to the pigs, sheep, chicken, duck slaughter cutting processing, puffed food production line, fruit grading, packaging line, aquatic products processing production line, frozen food production lines, battery manufacturing, beverage manufacturing industry, canning industry, agricultural product processing, industry, electronic industry, rubber and plastic industry, cosmetics industry, the general transport operations.

In addition to the above categories, mesh belt of the breed is many, such as Rod Chain Mesh Belt, accumulation type net belt, chain type net belt, Teflon mesh belt, ball type mesh belt etc.

There are many materials and types of mesh belt. Metal mesh belt have high strength, high wear resistance and corrosion resistance, and are widely used in industrial automation production lines. Nylon, polyester and other polymer material mesh belts have good wear resistance and flexibility, suitable for light load, low speed conveying scenarios, mesh size, pitch width, type can be customized according to actual use needs.

The products are mainly used in: glass bottles and jars, food, metal, utensils, chemical fiber, printing and dyeing, medicine, electronics, powder metallurgy, heat treatment, wood, logistics and other industries automatic devices and automatic assembly lines; The transmission and use of various kiln systems such as natural gas, coke oven gas and electronic infrared; Conveyor belts for food machinery, glass machinery, conveyor machinery.