Songjia Town, Lingcheng District, Dezhou City, Shandong Province, China [email protected] +86-15069278821

Features:

1) Chain plate belt is made of high quality metal sheet with robust surface and driven by chains; used for conveying very small products and top heavy loads.

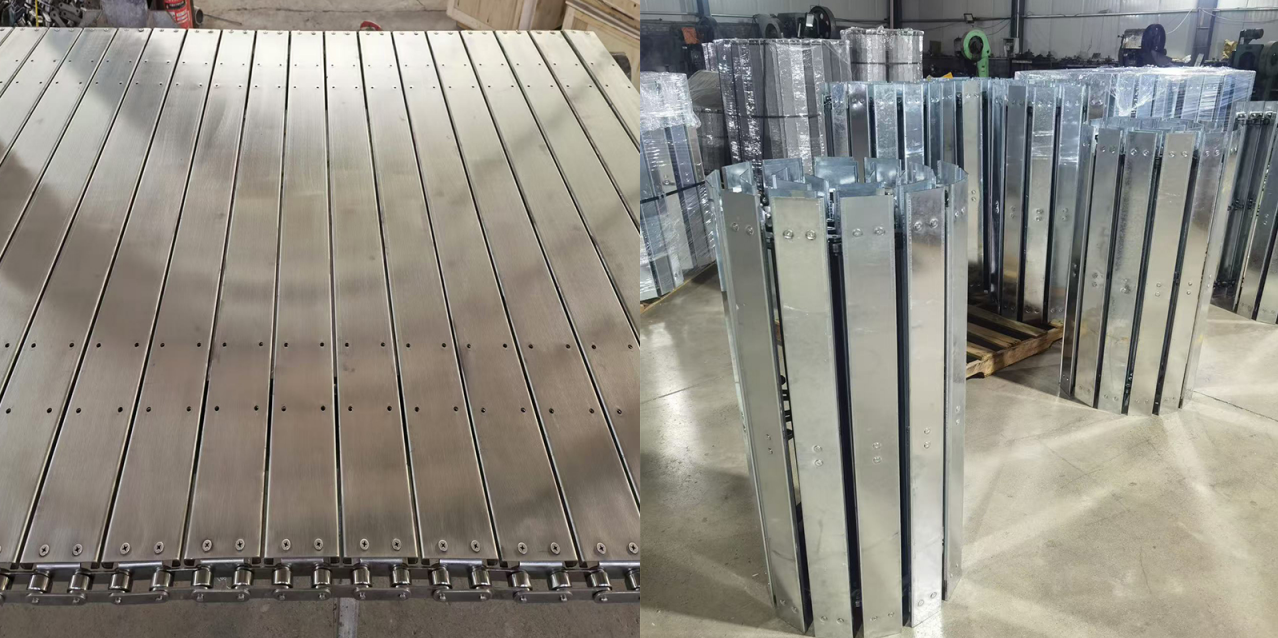

2) Suit for medium and heavy products transportation, big load capacity and durable.

3) High flexibility , make it level, tilt ,overturn and other difficult works in one process of transport line.

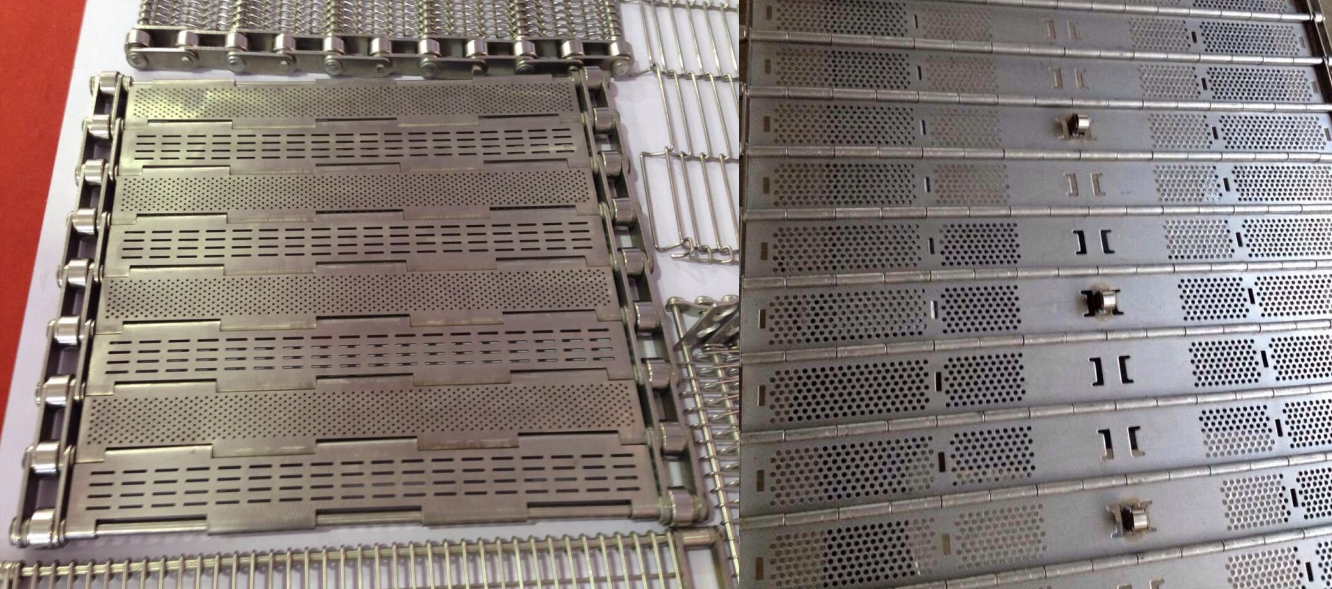

4) Punching can be customized used in different fields, to meet the different needs of all walks of life.

Applications:

It is widely used in vehicles, electrical assembly lines, animal slaughtering production lines, detergents, paper products, food and dairy and tobacco automatic conveying, distribution and post-packaging line conveying, as well as glass products and castings cooling and conveying.

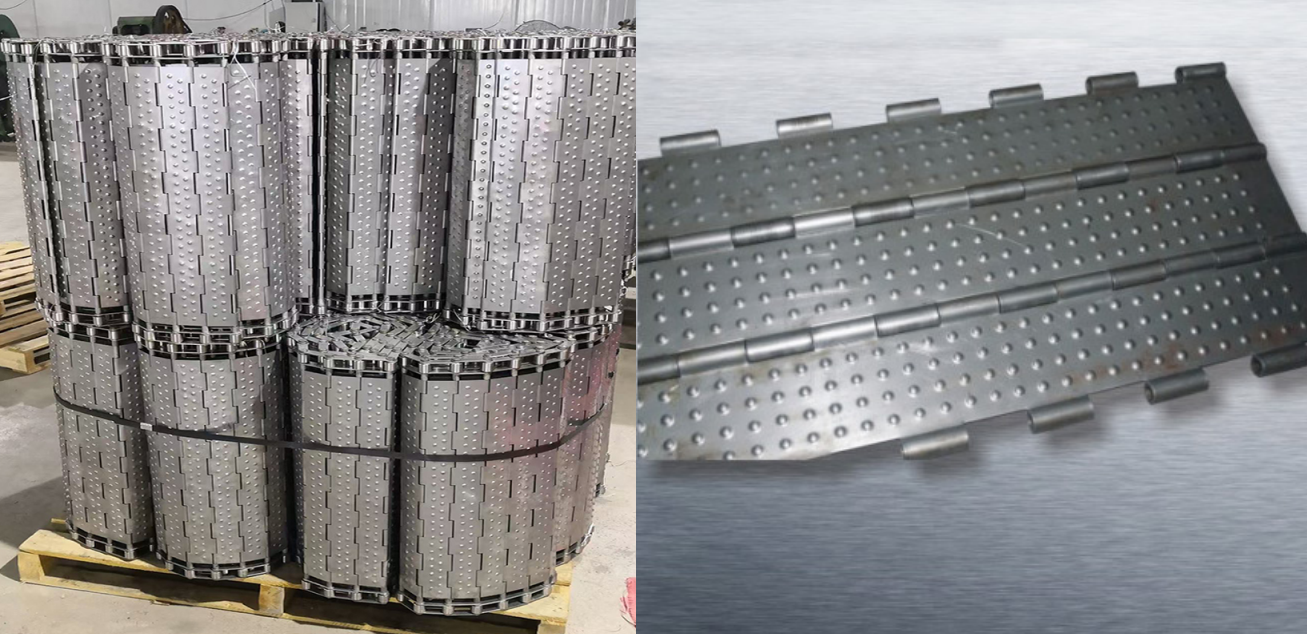

Chain plate conveyor belt has many varieties and specifications, mainly has the following several: stainless steel (carbon steel)chain plate conveyor belt, punching chain plate conveyor belt, chip conveyor chain plate conveyor belt, cleaning chain plate conveyor belts, flat top chain plate conveyor belt, engineering plastic chain plate conveyor belt and keel chain plate conveyor belt etc.. The width between 100mm-5000mm.

1) Chain plate conveyor belt is made of high quality metal plate with strong surface and driven by chains; used for conveying very small products and top heavy loads.

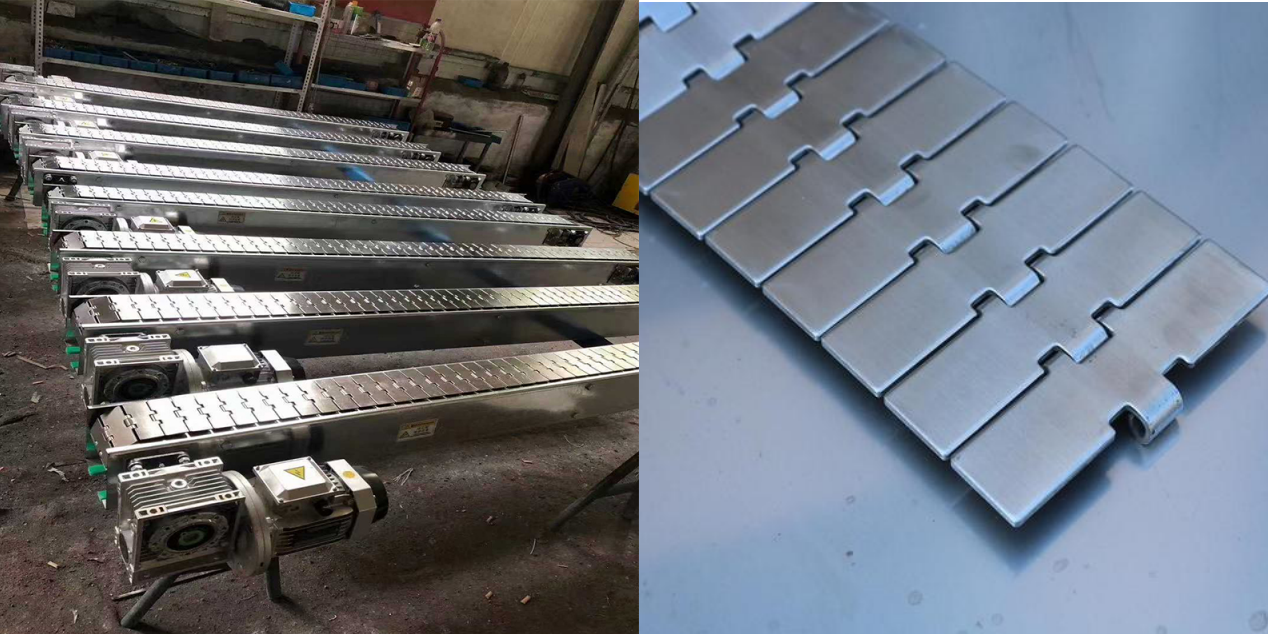

2) Running smoothly, easy to setup with a longer service life.

3) Suit for medium and heavy products transportation, big load capacity and durable.

4) High flexibility , make it level, tilt ,overturn and other difficult works in one process of transport line.

5) Punching can be customized used in different fields, to meet the different needs of all walks of life.

6) Flat-top chain plate conveyor belt is a special kind of chain plate conveyor belts with small friction, make it transport smoothly ; and simple structure make it easy to maintain.

It is widely used in food, canned food, medicines, beverages, cosmetics, motorcycle assembly line, animal slaughtering production line, washing supplies, paper products, condiments, dairy and tobacco automatic transmission, distribution, and after the packaging line conveyor ; Cooling conveyor of glass products castings and out-feed conveyor of processing iron, besides, different kinds of metal products can be convoyed too.

Chain plate conveyor belt in the transmission process, often appear unstable operation and the deviation phenomenon:

Maintenance methods are as follows:

1) The regulator chain plate conveyor belt tensioning axle, moderate elastic, To avoid damage of chain plate conveyor belt edge

2) Check whether there is an internal corrosion phenomenon of conveyor, the necessary replacement.

3) Check the chain drive shaft ends, whether synchronization,Sprocket tooth end whether the excessive wear and tear。

First of all, in the use of chain plate conveyor belt, should avoid direct contact with the heat source, should be at least one meters apart, in outdoor use, should avoid direct sunlight and other weather factors. And the conveying speed should be less than 2.5m/s. In the use process, should not be excessive tension of chain plate conveyor belt,In the guarantee chain plate conveyor belt and the chain wheel bite, not curved and try to keep the minimum tension.In the same conveyor, chain plate conveyor belt must use the same model and the same material.

Secondly, the chain plate conveyor belt began running, should ensure that the empty machine conveyor start. Because boot need considerable acceleration, if it starts, chain plate conveyor belt piled material, possible gear slippage, motor load is too higher series of problems. When stopping, also try to ensure that no material stacked on the chain plate conveyor belt. If it is a multistage chain plate conveyor belt began running, boot sequence should be from the forward after startup, shutdown sequence contrast.